LAUBLE

PRÄZISIONSDREHTEILE

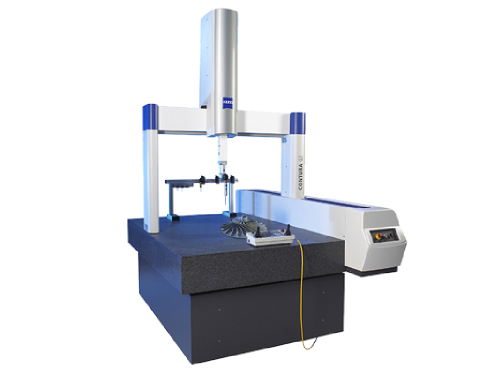

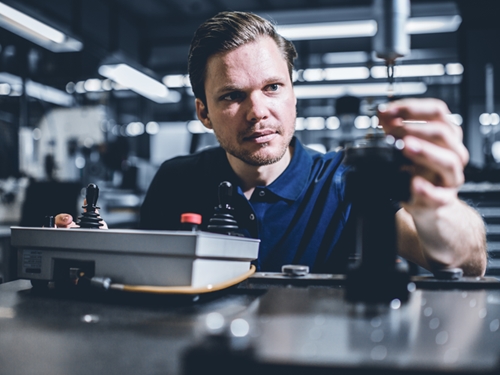

Contura G2

Contura G2The benchmark in the compact class

With outstanding scanning technology, ZEISS CALYPSO reference software and a coordinated overall design, ZEISS CONTURA consolidates its status as the benchmark in its class.

Control is independent of the computer via a user-friendly control panel. The progressive control lever provides easy and precise control of all axis movements. In CNC mode, the speed control is variable.

Flexible and reliable quality assurance

Flexible and reliable quality assuranceThe latest generation is now even more precise and offers a wide package of optical sensors in addition to additional measuring ranges.

Depending on the size, ZEISS CONTURA uses ceramic or CARAT guides for high rigidity, low thermal expansion and low moving mass. Wraparound air bearings in all three axes ensure consistent stability even at high travel speeds and during acceleration.

The floating glass-ceramic scales from ZEISS CONTURA are virtually expansion-free and therefore do not require additional temperature sensors or calculated compensation. They are protected against dirt and other influences in a manner suitable for the workshop.

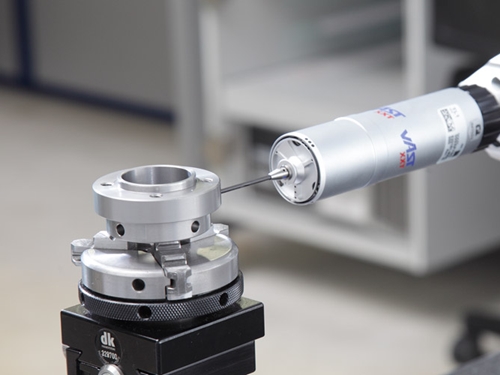

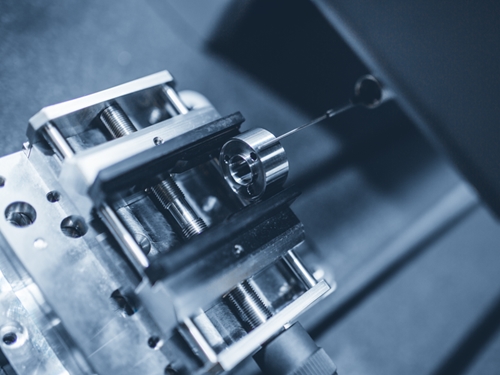

SURFCOM NEX 001

SURFCOM NEX 001The contour and surface measuring devices from ZEISS offer various sensors, some of which can be combined, for roughness measurements, contour measurements or both.

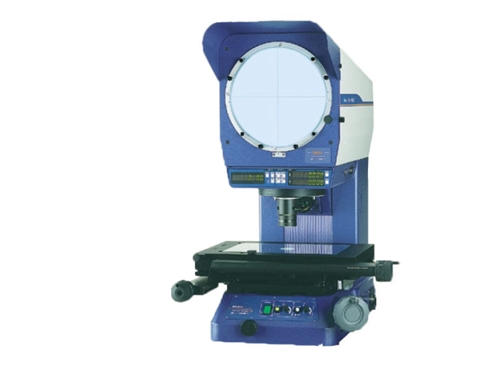

KEYENCE IM-7000 Measuring Projector

KEYENCE IM-7000 Measuring ProjectorKEYENCE's digital measurement projector combines conventional measurement methods while being faster and more accurate. Using height measurement probes, photoelectric proximity switches and optics, the IM-7000 produces clear measurement results in seconds at the touch of a button. A user-friendly and well-developed operating concept forms the basis for user-independent measurements. The generously designed measuring surface allows uncomplicated measurement of large components. It also allows a large number of components to be measured in a single step. Thus, the digital measuring projector is able to perform ninety-nine measurements on up to one hundred components in three seconds -

precision in best time!

HOMMEL-TURBO WAVE T8000

HOMMEL-TURBO WAVE T8000Flexible roughness and contour measurement

HOMMEL-ETAMIC CONTOUR 314

HOMMEL-ETAMIC CONTOUR 314Opticline Shaft Measurement

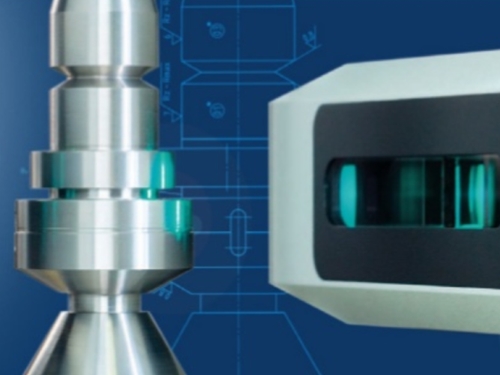

TESA MICROHITE 600

TESA MICROHITE 600Autonomous devices for measuring in one or two coordinate directions internal, external, step, height, depth and distance dimensions on geometric elements with flat, parallel or cylindrical surfaces.

The culmination point is automatically entered on bores and shafts - With "max.", "min." and "max.-min." memory function as dynamic measurement. By using the TESA IG-13 digital probe, squareness, straightness and parallelism deviations as well as radial and axial runout can also be recorded. Operating results according to ISO 1101.

Extremely accurate measuring of deviations from length, straightness and perpendicularity due to the automatic correction of the bias errors through CAA (Computer Aided Accuracy).

UHL MS4

UHL MS4High quality and robust video measuring microscope with motorized measuring stage made of standard components of our modular system.

Due to the modular design, a customer-specific device can be realized in a very short time.

Measuring projector with screen and zoom lens 10x

Measuring projector with screen and zoom lens 10x